Turbo Compressor NC series

Turbo compressor NC series is a low-pressure compressor that provides the operating range of 1.1 ~ 2.0 kgf/㎠ G. NC series is combined with aerodynamic design centrifugal compressor, air bearing and high-speed motor, proving an accurate pressure points on the application without the pressure loss or decompression, and will improve the productivity of customers through excellent reliability and supreme efficiency.

Suction Flow Rate : 12 ~ 230 ㎥/min |

|

Discharge pressure : 1.1 ~ 2.0 kgf/㎠ G |

|

Turndown : 70 ~ 100% |

|

Noise Level : Below 85dB(A) |

|

100% Oil-free system |

|

Compliance with ISO5389, ASME PTC 10 |

1) THE HIGHEST PERFORMANCE

Impeller, completed in optimized aerodynamic design and elemental technologies specialized in high rotation, such as PMSM, VFD are make performance of NC series high.

• Turbo compressor NC Series is capable of reducing the number of operating units and energy saving of 50-70% (40-50% reduced pressure loss savings, 20% compression efficiency) compared to the high-pressure compressor.

• Self-developed Permanent Magnet Synchronous Motor(PMSM) has a high efficiency and power factor of more than 95% for high speed operation, which operates the blower with negligible mechanical loss during operation thanks to the rotor of motor and impeller being directly coupled.

• VFD(Variable Frequency Drive) enables to remove waste of energy by controlling the rotational speed of PMSM in order to adjust discharge pressure and flow rate, in a wide operating range of 70~100%.

2) EXCELLENT RELIABILITY

Air bearing has been developed through the technical Know-How accumulated in an aircraft turbo engine development experience. Proven air bearing and patented cooling system with easy control system will ensure high reliability.

• Non-contact air bearing that utilizes the dynamic pressure of air fluid supplied the 100% oil- free compressed air and the structural stability.

• Patented cooling system that applied aircraft industry, such as ACM, ESC boasts enhanced cooling performance and no heat emission from the blower to the surroundings.

• Built-in logic alarms and self-diagnosis system in the blower can make stable operation continuously.

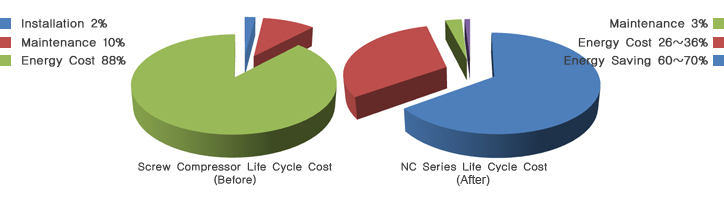

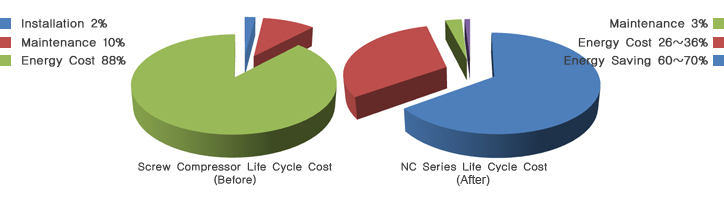

3) ECONOMICAL LIFE CYVLE COST

NC series can maximize the profitability of end users through significant reduction of LCC.

• NC series keep high productivity through reduced LCC compared to high pressure screw compressor.

• There is no lubricating oil or associated maintenance required by adopting the non-contact air bearing, only replacing or cleaning air filter and water-cooling components are needed. Air filter, composed of 2 stages, protects the mechanical and electrical components and increases their efficiency.

4) CUSTOMER ORIENTED TECHNOLOGY

User-friendly and eco-friendly technology is implemented for convenience.

• PLC and touch screen allow end-users to easily control, monitor and diagnose and to run in automated mode at constant speed, pressure, flow or dissolved oxygen control mode.

• Various languages are available including English, Chinese, Japanese, Korean, Turkish and Russian.

• It is possible to reduce the installation costs up to 40-50% and plug & play operation thanks to the small footprint and all-in-one package.

• It is operated with 100 oil-free by removing the lubrication system and has very low vibration of less than 1mm/s and noise levels in combination with non-contact air bearing and patented enclosure

Impeller, completed in optimized aerodynamic design and elemental technologies specialized in high rotation, such as PMSM, VFD are make performance of NC series high.

• Turbo compressor NC Series is capable of reducing the number of operating units and energy saving of 50-70% (40-50% reduced pressure loss savings, 20% compression efficiency) compared to the high-pressure compressor.

• Self-developed Permanent Magnet Synchronous Motor(PMSM) has a high efficiency and power factor of more than 95% for high speed operation, which operates the blower with negligible mechanical loss during operation thanks to the rotor of motor and impeller being directly coupled.

• VFD(Variable Frequency Drive) enables to remove waste of energy by controlling the rotational speed of PMSM in order to adjust discharge pressure and flow rate, in a wide operating range of 70~100%.

2) EXCELLENT RELIABILITY

Air bearing has been developed through the technical Know-How accumulated in an aircraft turbo engine development experience. Proven air bearing and patented cooling system with easy control system will ensure high reliability.

• Non-contact air bearing that utilizes the dynamic pressure of air fluid supplied the 100% oil- free compressed air and the structural stability.

• Patented cooling system that applied aircraft industry, such as ACM, ESC boasts enhanced cooling performance and no heat emission from the blower to the surroundings.

• Built-in logic alarms and self-diagnosis system in the blower can make stable operation continuously.

3) ECONOMICAL LIFE CYVLE COST

NC series can maximize the profitability of end users through significant reduction of LCC.

• NC series keep high productivity through reduced LCC compared to high pressure screw compressor.

• There is no lubricating oil or associated maintenance required by adopting the non-contact air bearing, only replacing or cleaning air filter and water-cooling components are needed. Air filter, composed of 2 stages, protects the mechanical and electrical components and increases their efficiency.

4) CUSTOMER ORIENTED TECHNOLOGY

User-friendly and eco-friendly technology is implemented for convenience.

• PLC and touch screen allow end-users to easily control, monitor and diagnose and to run in automated mode at constant speed, pressure, flow or dissolved oxygen control mode.

• Various languages are available including English, Chinese, Japanese, Korean, Turkish and Russian.

• It is possible to reduce the installation costs up to 40-50% and plug & play operation thanks to the small footprint and all-in-one package.

• It is operated with 100 oil-free by removing the lubrication system and has very low vibration of less than 1mm/s and noise levels in combination with non-contact air bearing and patented enclosure